Two Probe Method For Resistivity Measurement Of Insulators, TPX-200C

Product Details:

- Color Grey

- Weight 30 Kg Kilograms (kg)

- Application Laboratory Experiment

- Material Electronics

- Usage Laboratory Experiment

- Click to View more

Two Probe Method For Resistivity Measurement Of Insulators, TPX-200C Price And Quantity

- 1 Set

Two Probe Method For Resistivity Measurement Of Insulators, TPX-200C Product Specifications

- Electronics

- 30 Kg Kilograms (kg)

- Laboratory Experiment

- Grey

- Laboratory Experiment

Two Probe Method For Resistivity Measurement Of Insulators, TPX-200C Trade Information

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Delivery Point (DP), Telegraphic Transfer (T/T)

- 100 Set Per Month

- 1 Week

- Contact us for information regarding our sample policy

- Complete in all respect

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- All India

- ISO 9001: 2015 CE

Product Description

Two Probe Method For Resistivity Measurement Of Insulators, TPX-200C

With the endorsement of our experienced professionals, we are indulged in supplying, exporting and manufacturing of Two Probe Method For Resistivity Measurement Of Insulators, TPX-200C in Roorkee, Uttarakhand, India.

Two Probe Method for resistivity measurement of insulators at different temperatures. The Two Probe Method is one of the standard and most commonly used method for the measurement of resistivity of very high resistivity samples near insulators. The resistivity measurement of such samples is beyond the range of Four Probe Method.

Two Probe Method for resistivity measurement of insulators at different temperatures

The Two Probe Method is one of the standard and most commonly used method for the measurement of resistivity of very high resistivity samples near insulators. The resistivity measurement of such samples is beyond the range of Four Probe Method.

DESCRIPTION OF THE EXPERIMENTAL SET-UP

Two Probes Arrangement, TPA-01

It has two spring load contact probes. These probes move in a pipe and are insulated by PTFE washers. This probes arrangement is mounted in a suitable stand, which also holds the sample plate and RTD sensor. The stand also serves as the lid of PID Controlled Oven. PTFE coated leads are provided for connecting wit High Voltage Power Supply EHT-11C and Digital Picoammeter DPM-111C. With this set-up assuming max. Voltage = 1500V; current 10x10-12 A (max) and thicknexx of sample 1mm, the resistivity of the sample could be measured upto 1014 ohm.cm..

PID Controlled Oven, PID-200C

Specification same as PID-200 given in TPX-01, with extra attachment for connecting computer interface, SES-CAMM

DPM-111C

Specification as per item 3, on page 5 DPM-111 with extra attachement for connecting computer interface, SES-CAMM.

EHT-11C

Specification as per item 4, on page 5 EHT-11 with extra attachement for connecting computer interface, SES-CAMM.

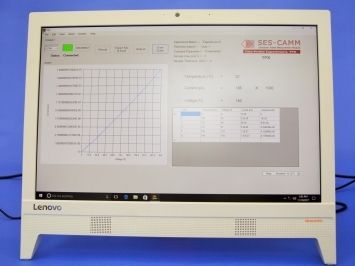

Computer Interface, SES-CAMM

An interface (SES-CAMM) provides the option to the user to interface it with the computer for acquiring and strong the data (temperature, current and voltage) and plotting in real time. The data is also stored in an excel file which can be used for further analysis. The software is menu driven and can be operated very easily.

The experiment is complete in all respect

Precision in Laboratory Measurements

The TPX-200C offers a precise mechanism for students and professionals engaging in laboratory experiments. With its two-probe configuration, it enables accurate assessment of electrical resistivity in insulators, contributing valuable data for material selection and analysis in electronics research.

Robust Construction, Reliable Performance

Designed with durability in mind, the TPX-200C is constructed from high-quality electronic materials with a solid grey finish. Its weight range between 25 and 30 kg ensures stability during experiments, supporting repeated usage without compromising measurement fidelity.

Versatility Across Research and Industry

Whether for academic laboratories or industrial quality control, the TPX-200C supports diverse experimental requirements. As an exporter, manufacturer, and supplier based in India, it is equipped to fulfill the needs of a global scientific community, ensuring accessible solutions for measuring resistivity in various insulator samples.

FAQs of Two Probe Method For Resistivity Measurement Of Insulators, TPX-200C:

Q: How does the TPX-200C two-probe method measure the resistivity of insulators?

A: The TPX-200C applies a known current through two probes placed on the insulator sample and measures the resulting voltage drop. Using these values, the device calculates the materials resistivity, offering high accuracy for laboratory experiments and research work.Q: What are the main benefits of using the TPX-200C in laboratory settings?

A: Its main benefits include reliable measurement accuracy, durable construction, and suitability for a wide range of electronic insulators. The instruments robustness and ease of use enhance laboratory workflow and provide essential insights in material science.Q: Where can the TPX-200C be used most effectively?

A: The TPX-200C is best utilized in laboratory environments such as research institutions, universities, and industrial research centers, particularly wherever precise measurement of insulator resistivity is required.Q: When should the two-probe method be chosen over other resistivity measurement techniques?

A: Choose the two-probe method, as with the TPX-200C, when measuring high-resistance materials or when simplicity in setup and operation is desired. This method is especially useful for quick and reliable laboratory experiments.Q: What is the process for conducting a resistivity experiment using the TPX-200C?

A: First, place the insulator sample between the two probes. Then, supply a controlled current and record the voltage drop across the material. The instrument processes these values to determine the resistivity, often displaying results directly or through connected software.Q: How heavy is the TPX-200C and does its weight affect installation or use?

A: The TPX-200C weighs between 25 and 30 kilograms, ensuring it remains stable during experiments. While manageable by most laboratory staff, its weight aids in reducing external disturbances, ensuring reliable measurements.Q: What makes the TPX-200C a suitable choice for exporters and suppliers in India?

A: Manufactured in India, the TPX-200C combines advanced technology with robust build quality, making it a reliable product for export. Its established performance and adherence to laboratory standards make it a preferred choice among suppliers globally.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free